-

Hlola i-Valve, I-Valve Yokunciphisa Ukucindezela, I-Valve Yokukhipha I-Valve, I-Instrument Valve

I-valve iyingxenye yokulawula kusistimu yokudlulisa uketshezi, enemisebenzi yokunqamula, ukulawula, ukuphambukisa, ukuvimbela i-countercurrent, ukuqiniswa kwengcindezi, ukuphambukisa noma ukukhululeka kwengcindezi echichimayo.

I-valve esetshenziswa ohlelweni lokulawula uketshezi, kusukela ku-valve yokumisa elula kakhulu kuya ohlelweni lokulawula oluzenzakalelayo oluyinkimbinkimbi kakhulu, izinhlobo zayo kanye nokucaciswa kwayo kuhluke kakhulu.Amavaluvu angasetshenziswa ukulawula ukugeleza kwezinhlobo ezahlukene zoketshezi olunjengomoya, amanzi, isitimu, imidiya eyonakalisayo ehlukahlukene, udaka, uwoyela, insimbi ewuketshezi kanye nemidiya ekhipha imisebe.Ngokusho kokuqukethwe, i-valve iphinde ihlukaniswe ngama-valve ensimbi ensimbi, ama-valve ensimbi, ama-valve ensimbi engagqwali (201,304,316, njll.), ama-valve ensimbi e-chromium molybdenum, i-chromium molybdenum vanadium steel valves, ama-valve ensimbi anezigaba ezimbili, ama-valve epulasitiki, ama-non -ama-valve enziwe ngokwezifiso ajwayelekile, njll.

-

I-Flat Welding Flange/ I-Welding Neck Flange/ I-Screwed Flange

Isethulo somkhiqizo:

Uxhumano lwe-Welding flange ukubeka amapayipi amabili, okokufakwa kwamapayipi noma izinto zokusebenza, kuqala ngalinye lifakwe endaweni yokushisela.Phakathi kwama-weld amabili, kanye namaphedi ane-flanged, ayeboshelwe kanye namabhawudi ukuze kuqedelwe ukuxhumana.I-Welding iyindlela yokuxhumana ebalulekile yokwakhiwa kwamapayipi okucindezela okukhulu.I-welding flange uxhumano kulula ukuyisebenzisa futhi ingamelana nokucindezela okukhulu.

-

I-Carbon steel Pipe Fitting A234WPB A420WPL6 ST35.8

Isethulo somkhiqizo:

Imikhiqizo eyinhloko yokufakwa kwepayipi lensimbi yensimbi ihlanganisa indololwane yensimbi ye-carbon steel, i-carbon steel flange, i-carbon steel tee, i-carbon steel tee, ipayipi lensimbi ekhethekile ye-carbon steel (ikhanda elikhulu nelincane), ikhanda le-carbon steel (ipayipi lepayipi), njll. Ukuqaliswa okuyinhloko amazinga afaka indinganiso kazwelonke, indinganiso yaseMelika, indinganiso yaseJapane, njll., phakathi kwayo izinga likazwelonke lihlanganisa nezinga le-Ministry of Chemical Industry standard, indinganiso yokufakwa kwamapayipi e-Sinopec, indinganiso yokufakwa kwamapayipi kagesi.Ukufakwa kwepayipi lensimbi ye-Carbon yigama elijwayelekile lokuxhuma, ukulawula, ukushintshwa, i-shunt, ukuvala uphawu kanye nezingxenye zokusekela ohlelweni lwamapayipi.Ukufakwa kwepayipi kuyisici esixhuma ipayipi nepayipi.Ukufakwa kwamapayipi omfutho ophakeme kulungele imishini ye-steam ye-high pressure, izinga lokushisa eliphezulu lamakhemikhali kanye nepayipi lokucindezela okukhulu, isikhungo samandla kanye nemikhumbi yokucindezela amandla e-nuclear, izesekeli eziphezulu ze-boiler nezinye izindawo ezikhethekile.Ukufakwa kwamapayipi kusetshenziswa kabanzi ekwakhiweni, embonini yamakhemikhali, ezimayini, ezamandla kanye neminye imikhakha eminingi yobunjiniyela.Indima yayo ebalulekile akufanele ishaywe indiva.

-

I-U Tubing Heat Exchanger Tube/ Ishubhu egobayo/Ishubhu le-Boiler

Isethulo somkhiqizo:

'U' ukugoba kwenziwa inqubo yokusebenza ebandayo.

Ukugoba u-'U' kwenziwa kurediyasi edingekayo ngokwemidwebo yamakhasimende.

Ingxenye yokugoba kanye nomlenze wamayintshi ayisithupha ingcindezi ekhululwe ukushisisa ukumelana.

Igesi ye-inert (i-Argon) idlula kuyo ngezinga lokugeleza elidingekayo ukuze kugwenywe i-oxidation ku-ID.

Irediyasi ihlolelwa i-OD yayo kanye nokuncipha kodonga ngokucaciswa okunconyiwe.

Izakhiwo ezibonakalayo kanye nesakhiwo esincane kuhlolwa endaweni emithathu ehlukene.

Ukuhlolwa okubonakalayo kokuphaphatheka nokuqhekeka kwenziwa nge-Dye Penetrant Test.

Ishubhu ngalinye libe selihlolwa i-hydro ngengcindezi enconyiwe ukuze kubhekwe ukuvuza.

Ukuhlolwa kwebhola likakotini kwenziwa ukuhlola ukuhlanzeka kwe-ID yeshubhu.

Ngemuva kwalokho zifakwe emanzini anosawoti, zomisiwe, ziphawulwe futhi zipakishwe.

-

I-A234 WPB SS400 ST35.8 P235GH Carbon Steel Elbow

Isethulo somkhiqizo:

Ohlelweni lwamapayipi, indololwane iwukufaniswa kwepayipi okushintsha isiqondiso sepayipi.Ngokusho kwe-Angle, kunezintathu ezivame ukusetshenziswa kakhulu i-45 ° kanye ne-90 ° 180 °, ngaphezu kwezidingo zobunjiniyela kanye nokunye ukugoba kwe-Angle okungavamile njengo-60 ° ngokusho kwephrojekthi.Izinto zendololwane zifaka i-cast iron, insimbi engagqwali, i-alloy steel, insimbi ekhohlakala, i-carbon steel, izinsimbi ezingezona ayoni namapulasitiki.

Izindlela zokuxhuma nepayipi yilezi: i-welding eqondile (indlela evame ukusetshenziswa kakhulu) uxhumano lwe-flange, uxhumano lwe-hot melt, uxhumano lwe-electric melt, uxhumano lwentambo nokuxhumeka kwepulaki, njll Ngokusho kwenqubo yokukhiqiza, ingahlukaniswa: indololwane, indololwane yokunyathela, indololwane yokuphusha, indololwane yokuphonsa, indololwane yokushisela izinqe, njll. Amanye amagama: ukugoba okungama-degree angu-90, ukugoba kwe-engeli yesokudla, njll.

-

I-alloy Steel Pipe Fitting A234WP12 P1 PA22 P5

Isethulo somkhiqizo:

I-alloy Steel Pipe fittings yitemu elijwayelekile lezingxenye ezixhumayo, ezilawulayo, ezishintshayo, eziphambukisayo, ezivalayo futhi ezisekelayo ohlelweni lwamapayipi.Ukufakwa kwepayipi yingxenye exhuma ipayipi libe yipayipi.Ukufakwa kwamapayipi okucindezela okuphezulu kulungele imishini ye-steam ye-high pressure, izinga lokushisa eliphezulu lamakhemikhali kanye nepayipi lokucindezela okukhulu, isikhungo samandla kanye nemikhumbi yokucindezela isitshalo samandla enyukliya, izesekeli ze-boiler ezicindezelayo kanye nezinye imvelo ekhethekile.Ukufakwa kwamapayipi kusetshenziswa kabanzi emikhakheni eminingi yobunjiniyela njengokwakha, imboni yamakhemikhali, izimayini namandla.Iqhaza layo elibalulekile akufanele lishaywe indiva.

-

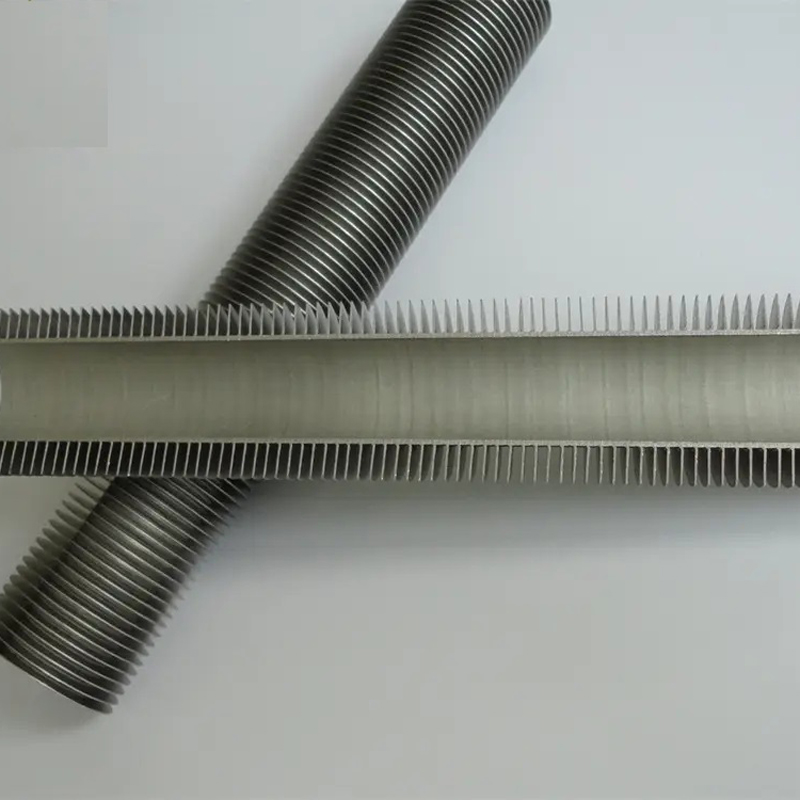

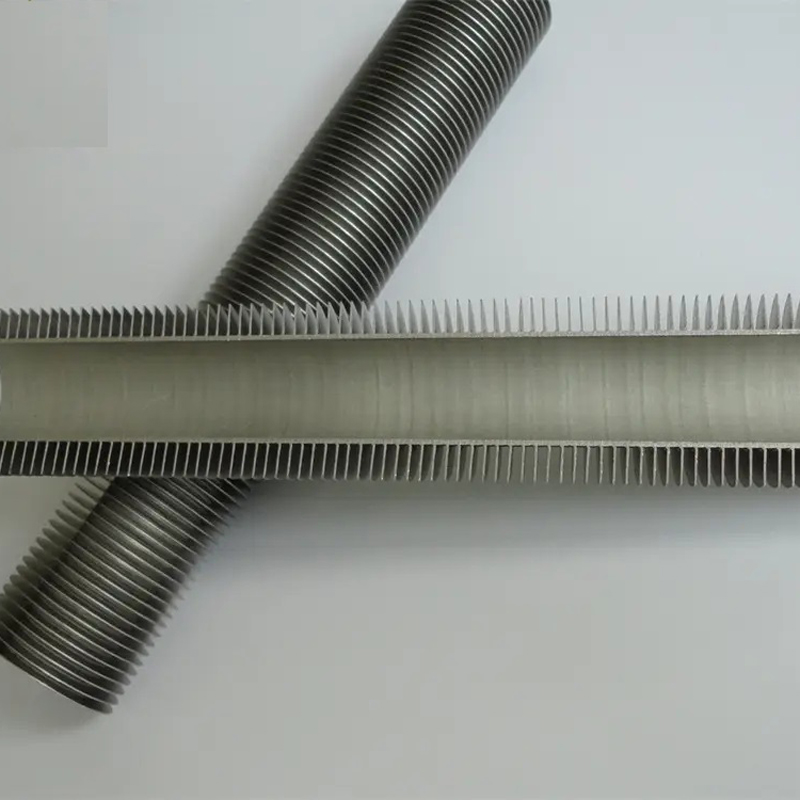

I-Heat Exchanger Finned Tube

Isethulo somkhiqizo:

I-Wing tube heat exchanger iyisishintshi sokushisa se-tubular esinamaphiko, esingakhiwa ishubhu elilodwa noma amaningana ama-fin futhi angaba negobolondo noma igobolondo.Kungumshini wokushisa omusha ofanele i-gas-liquid kanye ne-steam-liquid engenziwa ngokwezifiso ngokuvumelana nezimo zepharamitha;I-fin tube iyingxenye eyisisekelo ye-fin heat exchanger.Ukuze kuthuthukiswe ukusebenza kahle kokushintshaniswa kokushisa, amaphiko avame ukungezwa phezu kweshubhu yokushintsha ukushisa, ukuze kwandiswe indawo yangaphandle yeshubhu yokudlulisa ukushisa, ukuze kufezwe injongo yokuthuthukisa ukusebenza kahle kokudlulisa ukushisa.

-

304, 310S, 316, 347, 2205 Ukufakwa Kwepayipi Elingenasici

Isethulo somkhiqizo:

Ukufakwa kwamapayipi angagqwali yitemu elijwayelekile lezingxenye ezixhumayo, ezilawulayo, ezishintshayo, eziphambukisayo, ezivalayo nezisekelayo ohlelweni lwamapayipi.Ukufakwa kwepayipi yingxenye exhuma ipayipi libe yipayipi.Ukufakwa kwamapayipi okucindezela okuphezulu kulungele imishini ye-steam ye-high pressure, izinga lokushisa eliphezulu lamakhemikhali kanye nepayipi lokucindezela okukhulu, isikhungo samandla kanye nemikhumbi yokucindezela isitshalo samandla enyukliya, izesekeli ze-boiler ezicindezelayo kanye nezinye imvelo ekhethekile.Ukufakwa kwamapayipi kusetshenziswa kabanzi emikhakheni eminingi yobunjiniyela njengokwakha, imboni yamakhemikhali, izimayini namandla.Iqhaza layo elibalulekile akufanele lishaywe indiva.

-

I-alloy Stainless Copper Steel Fin Tube

Isethulo somkhiqizo:

Isigaba se-trapezoidal esakhiwe nge-calendering ye-fin tube emise okwe-L iyahambisana nobukhulu bokusabalalisa ukuminyana kokugeleza kokushisa, futhi ingxenye ihlanganiswe eduze futhi ukusebenza kahle kokushisa kuphezulu, okuqeda ukumelana nokushisa okubangelwa ingxenye. igebe.

Izinga lokushisa lokusebenza: 230 ℃

Izici: ukusetshenziswa kwenqubo yokuvunguza, ukusebenza kahle kokukhiqiza okuphezulu, ibanga elifanayo, ukudluliswa kokushisa okuhle, isilinganiso esiphezulu se-wing ratio, i-tube yesisekelo ingavikelwa ekugugulekeni komoya.

Isicelo: ikakhulukazi esetshenziswa petrochemical, amandla kagesi, iphepha, ugwayi, ukushisisa isakhiwo kanye nezinye izimboni air cooler, air heater kanye embonini yokudla plant amaprotheni powder, isitashi kanye nezinye isifutho omiswe uhlelo heater emoyeni. -

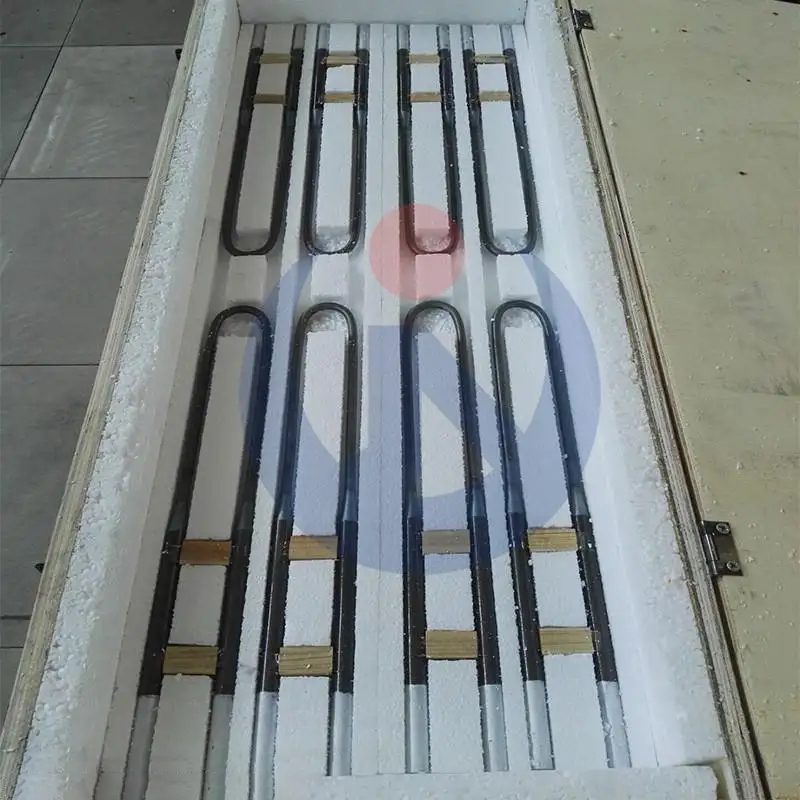

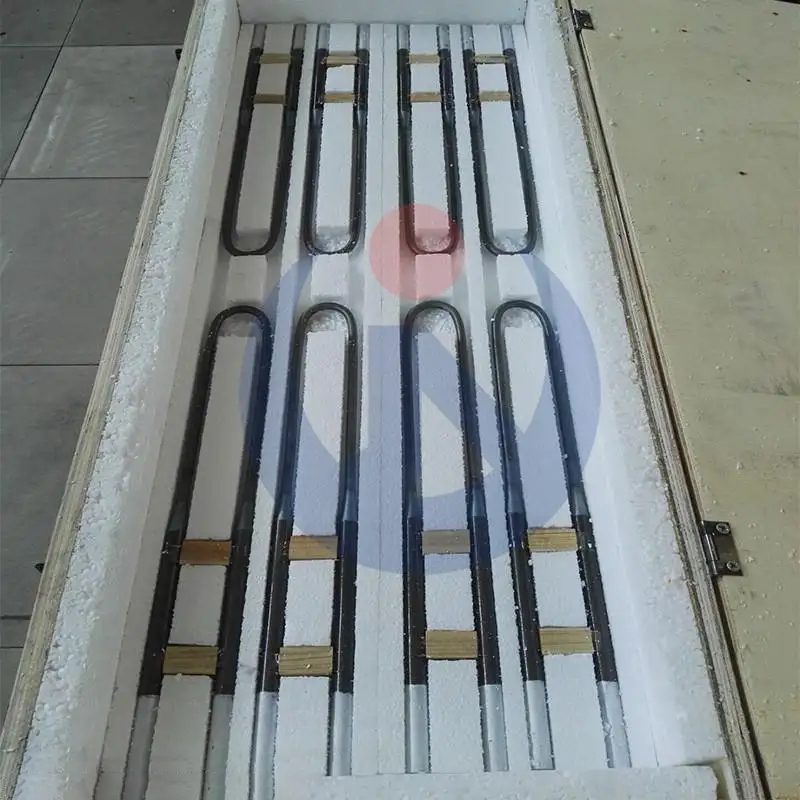

Insimbi Engagqwali/ Nickle Alloy U Bend Tubes

Isethulo somkhiqizo:

Ishubhu ye-U ivamise ukusetshenziselwa ukushintshanisa ukushisa kuketshezi lwenqubo olunamaradiyetha amakhulu.Uketshezi lumpontshelwa ngaphandle ngepayipi, bese ludlulela ku-U-junction, bese lubuyela emuva ngepayipi elihambisana nolayini ongenayo.Ukushisa kudluliselwa ngodonga lweshubhu kumpahla yokugoqa.Lo mklamo usetshenziselwa izinhlelo zokusebenza zezimboni, lapho amashubhu amaningi e-U angathululelwa ezitsheni zamafutha eziqukethe amandla okushisa aphezulu.

-

304, 310S, 316, 347, 2205 I-Stainless Flange

Isethulo somkhiqizo:

I-Flange, eyaziwa nangokuthi i-flange flange disc noma i-rim.Imvamisa isho ukuvulwa emaphethelweni omzimba wensimbi ofana nediski.Izimbobo eziningana ezingaguquki zisetshenziselwa ukuxhuma ezinye izingxenye futhi zisetshenziswa kabanzi emishinini ehlukahlukene yokuxhuma nokuxhuma amapayipi.I-Flange izingxenye ezixhunywe phakathi kwe-shaft ne-shaft ukuze kuxhunywe iziphetho zamapayipi futhi ibuye isetshenziswe endaweni yokungena nokuphuma kwezinto zokusebenza ukuze kuxhunywe amadivaysi amabili afana ne-reducer flange.

I-Flange iyisici esibalulekile sokuxhuma amapayipi futhi isetshenziswa kabanzi emikhakheni ehlukahlukene yezimboni.Umsebenzi wayo oyinhloko ukuxhuma ipayipi, ukuze uhlelo lwepayipi lube nokufaka uphawu oluhle nokuzinza.Ama-Flanges asebenza ezinhlobonhlobo zamapayipi.Ama-flanges angaxhunywa kumapayipi ahlukahlukene, okuhlanganisa amapayipi amanzi, amapayipi omoya, amapayipi amapayipi, amapayipi amakhemikhali nokunye.Kungakhathaliseki ukuthi ku-petrochemical, ukwakhiwa kwemikhumbi yamandla, ukucubungula ukudla, imithi kanye nezinye izimboni, ingabona i-flange.Ama-Flange ahlanganisa amasistimu amapayipi amaningi, imidiya, amazinga okucindezela kanye nezinga lokushisa.Emkhiqizweni wezimboni, ukukhethwa okulungile nokusetshenziswa kwe-flange kuyisiqinisekiso esibalulekile sokuqinisekisa ukusebenza okuphephile kwesistimu yamapayipi.

-

304, 310S, 316, 347, 2205 I-Stainless Cut - I-Valve Evaliwe, I-Ball Valve, I-Butterfly Valve

Isethulo somkhiqizo:

I-valve iyithuluzi elisetshenziselwa ukulawula indlela, ingcindezi nokugeleza kwesistimu yoketshezi.Kuyithuluzi lokugeleza noma ukumisa i-medium (uketshezi, igesi, impushana) epayipini nezinto zokusebenza nokulawula izinga lokugeleza kwalo.

Ivalvu iyingxenye yokulawula ohlelweni lokulethwa koketshezi lwamapayipi, esetshenziselwa ukushintsha ingxenye yokufinyelela kanye nesiqondiso sokugeleza okumaphakathi, nemisebenzi yokuphambukisa, ukusika, ukugoqa, ukuhlola, ukuphambukisa noma ukukhipha ingcindezi echichimayo.Amavalvu asetshenziselwa ukulawula uketshezi, kusukela ku-valve yokumisa elula kakhulu kuya ohlelweni lokulawula oluzenzakalelayo oluyinkimbinkimbi kakhulu olusetshenziswa ezinhlobonhlobo zamavalvu, izinhlobo zawo ezihlukahlukene kanye nokucaciswa kwawo, ububanzi obuncane be-valve kusukela ku-valve yensimbi encane kakhulu kuya kububanzi obungu-10m wezimboni. i-valve yepayipi.Ingasetshenziselwa ukulawula ukugeleza kwezinhlobo ezehlukene ezifana namanzi, umusi, uwoyela, igesi, udaka, imidiya eyonakalisayo ehlukahlukene, insimbi ewuketshezi noketshezi olukhipha imisebe.Ukucindezela kokusebenza kwe-valve kungaba kusuka ku-0.0013MPa kuya ku-1000MPa, futhi izinga lokushisa lokusebenza lingaba ngu-c-270 ℃ kuya kumazinga okushisa aphezulu angu-1430 ℃.