SA588 SA387 Ingxubevange Yensimbi Plate

Umthelela wezakhi ze-alloy kuzakhiwo zenqubo yensimbi

1. Ithonya lama-elementi e-alloy ekusebenzeni kokusakazwa kwensimbi

Uma izinga lokushisa liphansi lemigqa yesigaba esiqinile nesoketshezi futhi indawo yokushisa ye-crystallization iyancipha, ukusebenza kokulingisa kuba ngcono.Umthelela wama-elementi e-alloy ekusebenzeni kokusakaza uncike kakhulu ethonyeni lawo kumdwebo wesigaba se-Fe-Fe3C.Ngaphezu kwalokho, izakhi eziningi, ezifana ne-Cr, Mo, V, Ti, Al, zakha i-carbide ephakeme kakhulu noma izinhlayiya ze-oxide ensimbi, ezikhulisa i-viscosity yensimbi, zinciphise uketshezi, futhi zonakalise ukusebenza kokulingisa.

2. Umthelela wezakhi ze-alloy ku-plastic machining yensimbi

Ukucutshungulwa kwePlastiki kuhlukaniswe ngokucubungula ukushisa nokucubungula okubandayo.Izakhi ze-alloy zibe isixazululo esiqinile, noma ukwakheka kwe-carbide (efana ne-Cr, Mo, W, njll.), ithuthukisa ukumelana nokushisa kwensimbi kanye nokwehla okuphawulekayo kwe-thermoplasticity futhi kulula ukuyifaka nokuqhekeka.Ukusebenza kwenqubo yokushisa okushisayo kwensimbi evamile ye-alloy kubi kakhulu kune-carbon steel.

3. Umphumela wezakhi ze-alloy kuzakhiwo zokushisela zensimbi

Izakhi ze-alloy zonke zithuthukisa ukucimeka kwensimbi, zikhuthaza ukwakheka kwezicubu eziphukayo (i-martensite), futhi zenze ukusebenza kokushisela kube kubi.Kodwa-ke, insimbi iqukethe inani elincane le-Ti ne-V, elingathuthukisa ukusebenza kwe-welding yensimbi.

4. Umthelela wezakhi ze-alloy ekusebenzeni kokusika kokusika kwensimbi kuhlobene eduze nobulukhuni bensimbi, insimbi ifaneleka ukusika ukucubungula ubulukhuni bebanga le-170 HB ~ 230 HB.Ukusebenza kokusika kwensimbi evamile ye-alloy kubi kakhulu kune-carbon steel.Kodwa-ke, ukungezwa okufanele kwe-S, P, Pb nezinye izakhi kungathuthukisa kakhulu ukusebenza kokusika kwensimbi.

5. Ithonya lezakhi ze-alloy ekusebenzeni kwenqubo yokwelapha ukushisa kwensimbi

Ukusebenza kwenqubo yokwelapha ukushisa kubonisa ubunzima bokwelashwa kokushisa kwensimbi kanye nokuthambekela kokwelashwa kokushisa.Ihlanganisa ikakhulukazi ukuqina, ukuzwela ukushisa ngokweqile, i-temering embrittlement kanye ne-oxidative decarbonization.Insimbi ye-alloy ine-quenability ephezulu, futhi indlela yokupholisa kancane kancane ingasetshenziswa lapho icisha, enganciphisa ukuguquguquka nokuthambekela kokuqhekeka kwe-workpiece.Ukwengeza i-manganese ne-silicon kuzokwandisa ukuzwela kokushisa okweqile kwensimbi.

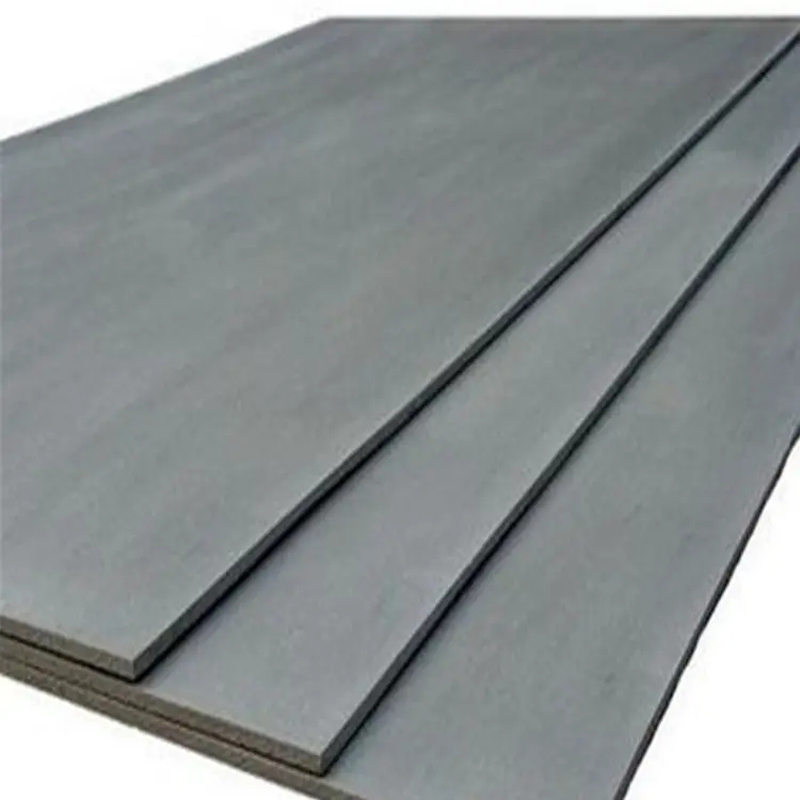

Imininingwane Yomkhiqizo

| Ibanga Lensimbi: | 15CrMo, 12CrMoV, EN: S235JR, S275JR, S355JR, S420NL, S460NL, S500Q, S550Q, S620Q, S690Q ASTM: Grade B, Grade C, Grade D, A36, Grade 36, Grade 40, Grade 42, Grade 50, Grade 55, Grade 60, Grade 65, Grade 70, GradeJIS:SPHC, SS400, SPFC, SPHD, SPHE |

| Okujwayelekile: | I-DIN EN 10083,ASME SA516, ASTM A203M,ASME SA588,ASME SA387,SAE1045 I-JIS G4051, AISI, BS |

| Ubukhulu: | 1.0-300mm |

| Ububanzi: | 100-4500mm, noma ngokusho kwesicelo esikhethekile sekhasimende |

| Ubude: | 1-20meters, noma ngokusho kwesicelo esikhethekile sekhasimende |

| Iphakheji: | Khipha Iphakheji Elijwayelekile |

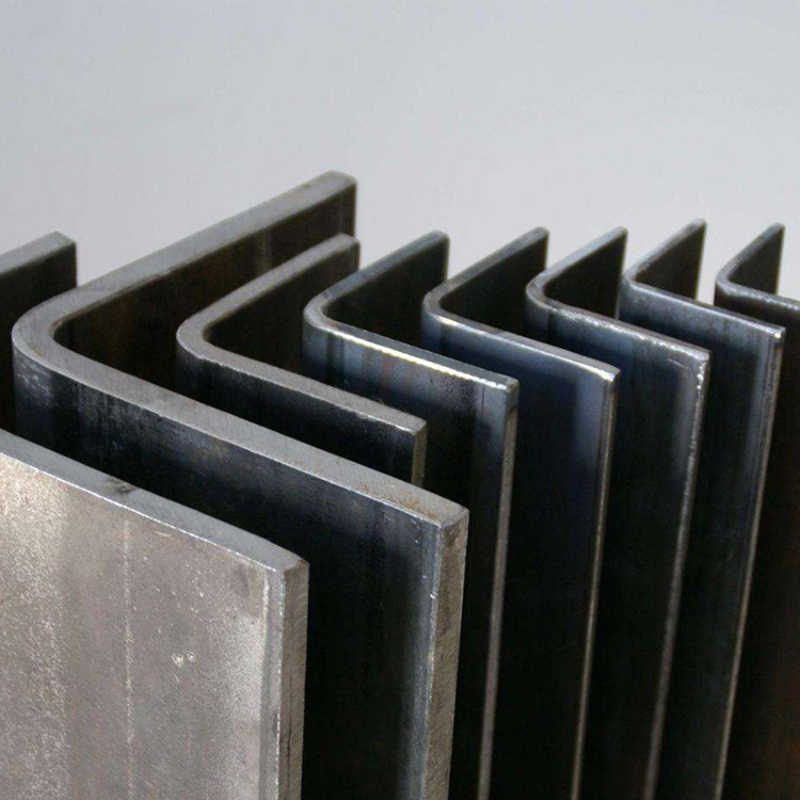

| Isicelo: | 1.Imishini, izimboni zemikhumbi yokucindezela. 2.Isakhiwo somkhumbi, ukwakhiwa kobunjiniyela. 3.Imoto, Amabhuloho, Izakhiwo. 4.Ukukhiqiza imishini, i-Pavement slab, njll. |

| I-Mill MTC: | Ihlinzekwa ngaphambi kokuthunyelwa |

| Ukuhlola: | Ukuhlolwa komuntu wesithathu kungamukelwa, i-SGS, i-BV, i-TUV |

| I-Mount Port: | Noma yiliphi ichweba eChina |

| Isikhathi Sokuhweba: | FOB, CIF, CFR, EXW, njll. |

| Isikhathi senani: | TT noma LC lapho ubona |

| Amasevisi ethu: | Singasika futhi sigobe ipuleti lensimbi ngokuya ngesidingo sekhasimende noma umdwebo, ukupakishwa ngokwesicelo samakhasimende |

Umbukiso Wemboni