Ishubhu yensimbi engenamthungo ye-Heat exchanger / Boiler pipe

Isethulo somkhiqizo

I-Quenching (Ukuqina, okubuye kwaziwe ngokuthi i-quenching) -ishubhu likabhayela elinomfutho ophezulu oshisiswe ngokulinganayo kuze kufike ezingeni lokushisa elifanele, bese licwiliswa ngokushesha emanzini noma emafutheni lapho lipholisa ngokushesha, noma emoyeni noma endaweni ebandayo, ukuze ibhayela lomfutho ophezulu tube ukuthola ubulukhuni obudingekayo.

Ipayipi likabhoyela elinengcindezi ephezulu lizoba brittle ngemva kokucisha.Ngesikhathi esifanayo, ukucindezeleka okubangelwa ukucisha nokupholisa kungaphula ipayipi le-boiler elicindezelayo ngokushaya ukukhanya.Ukuqeda i-brittleness, indlela yokwelapha yokushisa ingasetshenziswa.I-Refire iwukushisa kabusha ishubhu likabhayela elinomfutho ophezulu ukuze libe izinga lokushisa elifanele noma umbala, bese unikeza amakhaza abukhali.Nakuba ubulukhuni bepayipi le-boiler elinomfutho ophezulu buncishisiwe kancane, bungakhuphula ukuqina kwepayipi le-boiler elicindezelayo futhi linciphise ukuqina kwalo.

I-Annealing-annealing iyindlela yokuqeda ukucindezeleka kwangaphakathi kanye nensimbi yepayipi elibilisa umfutho ophezulu.Indlela ye-Annealing iwukushisa izingxenye zensimbi ezingeni lokushisa elibucayi, bese ufaka emlotheni owomile, umcako, i-asbestos noma uvale esithandweni somlilo, wenze kuphole kancane.

Ubulukhuni (Ubulukhuni) -yikhono lempahla ukumelana nokungena kwangaphandle.Umhloli wokuqina unembile kakhulu, okuyindlela evamile yokuhlola ubulukhuni.Indlela yokuhlola evame ukusetshenziswa kakhulu umshini wokuhlola ubulukhuni be-Rockwell umshini wokuhlola ubulukhuni be-Rockwell usebenzisa ukujula kwedayimane eliphuthunyiswe ensimbi ukuze kutholakale ubulukhuni bepayipi likabhayela elinomfutho ophezulu, ukujula kokungena kukhudlwana, kuncane ubulukhuni.Idayimane ligijima lingene ekujuleni kwensimbi ukuze libonise inombolo elungile evela kusikhombi, esibizwa ngokuthi inombolo yokuqina kwe-Rockwell.

Forging-iyisando ukwenza insimbi ibe ijamo elithile & lt;ukubumba & gt;Indlela, lapho ukushisa kwe-tube ku-boiler yokucindezela okuphezulu kuya ekushiseni okukhangayo, kungenziwa ekwenzeni, ukugoba, ukudweba, ukubumba kanye neminye imisebenzi.Amashubhu amaningi kabhayela wengcindezi ephezulu kulula ukuwenza uma eshiselwa abebomvu ngokugqamile.

I-Britittleness-ibonisa ubunjalo bepayipi likabhayela elinomfutho ophezulu eligqabuka kalula, insimbi ecijile iyaphuka, ngisho nokuwa phansi izogqashuka.I-Britittleness nobulukhuni kuhlobene eduze, ubulukhuni obuphezulu be-20 # ukunemba kwepayipi lensimbi ngokuvamile libuye libe brittleness.

i-ductility- (ebuye yaziwe ngokuthi ukuthamba) iwuhlobo lokuguquguquka okungapheli kwensimbi ngamandla angaphandle ngaphandle kokuhlukana, i-ductility yepayipi likabhayela elinomfutho ophezulu lingadonselwa emigqeni emincane.

I-Elastic-isakhiwo seshubhu lebhayela elinomfutho ophezulu lonakaliswa amandla angaphandle, lapho amandla angaphandle eqedwa.Insimbi yasentwasahlobo iyinto enwebeka kakhulu.

Ukuqina-ukumelana nensimbi ekubhobozeni kwangaphandle noma ukusika kungakhuphula ukuqina kweshubhu lokucindezela okuphezulu indlela evamile yokucisha.

Ukusebenza- -okwaziwa nangokuthi ukonakala, kungenye into emele i-ductility yensimbi noma ukuthamba.Umbukiso uyisakhiwo sensimbi esamukela isando esakhiwe noma esiginqikayo.

Ukuqina yikhono lepayipi likabhoyela elinengcindezi ephezulu ukumelana nokudlidliza noma umthelela.Ukuqina kumane nje kuphambene nokuqina.

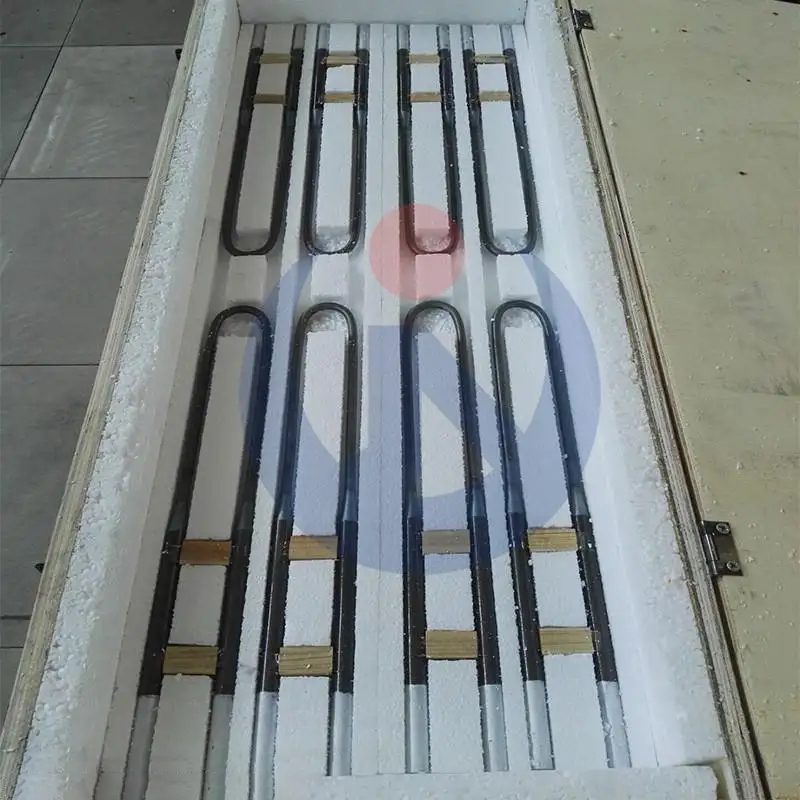

Enqubweni yokukhiqiza ipayipi yensimbi engenamthungo ye-boiler, ukwelashwa kokushisa kuyinqubo eyinhloko.Ukwelashwa kokushisa kunomthelela obalulekile kwikhwalithi yangaphakathi kanye nekhwalithi yendawo yepayipi yensimbi engenamthungo, ebaluleke kakhulu ekukhiqizeni ipayipi yensimbi engenamthungo.

Inkampani yethu yamukela ukwelashwa kokushisa okungeyona i-oxidation, ukukhiqizwa kwamapayipi ensimbi anenhlangano ezinzile ye-metallographic kanye nekhwalithi enhle yangaphakathi nangaphandle, isebenzisa ukutholwa kwe-eddy yamanje kanye ne-ultrasonic othomathikhi, ipayipi lensimbi ngalinye ukuze kutholwe iphutha lamanje le-eddy kanye nokutholwa kwamaphutha e-ultrasonic.Ngesilinganiso sobukhulu be-ultrasonic kanye nemisebenzi yokuthola amaphutha e-oblique, ingakwazi ukubona kahle amaphutha agqinsile epayipini lensimbi.

Imininingwane Yomkhiqizo

| Ibanga Lensimbi: | 106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT,ND-Steel Pipe |

| Okujwayelekile: | ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,DIN 17459,DIN17175,EN10216,BS3605,BS3059 |

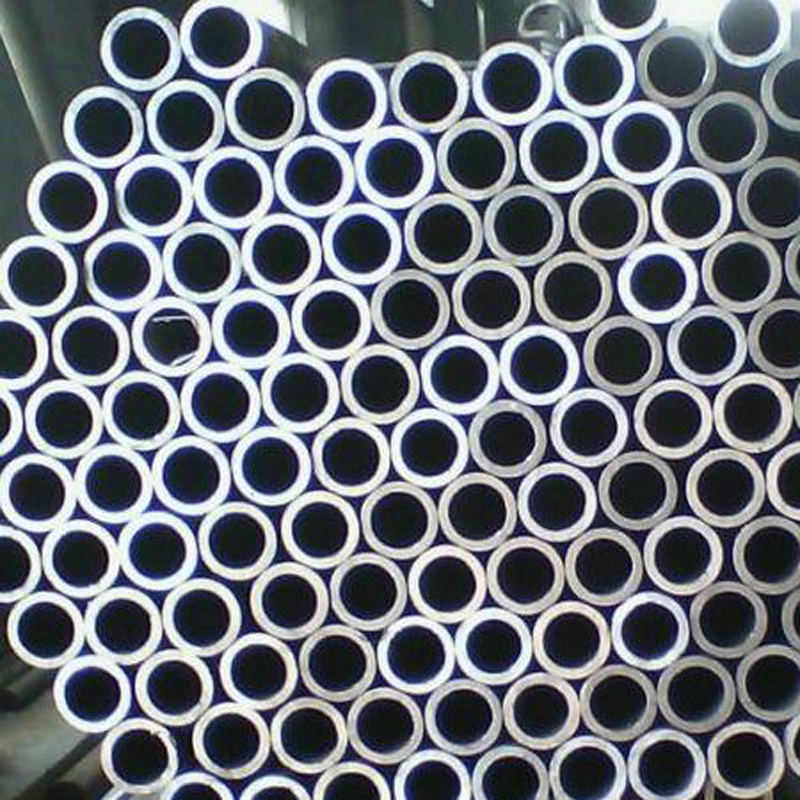

| Ukucaciswa: | I-Outdiameter 10 ~ 508mm |

| Wt: | 1.0-30mm, noma ngokusho kwesicelo esikhethekile sekhasimende |

| Ubude: | 2-20meters, noma ngokusho kwesicelo esikhethekile sekhasimende |

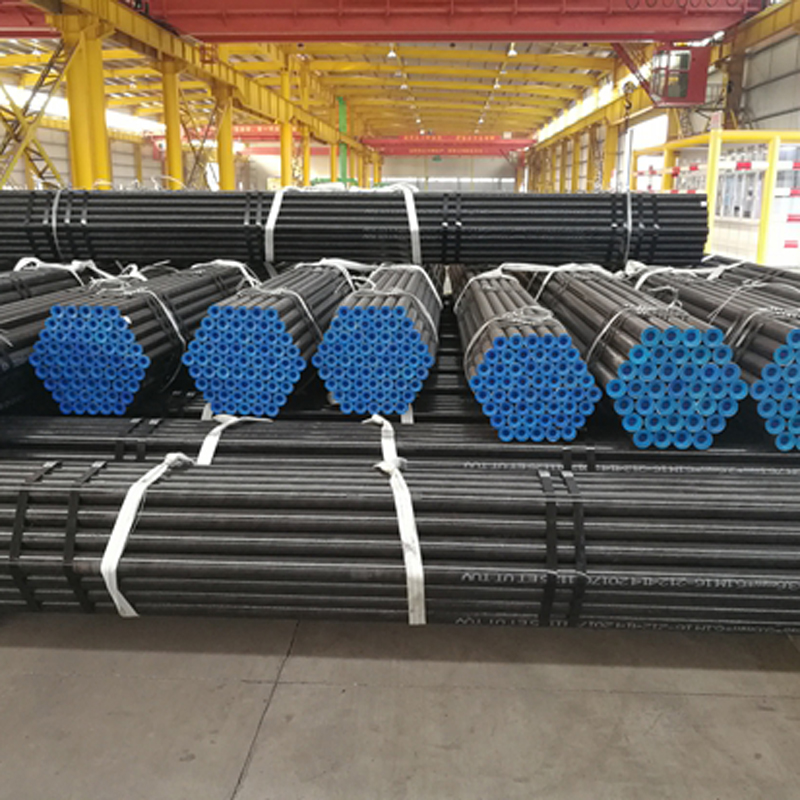

| Iphakheji: | Khipha Iphakheji Elijwayelekile |

| Izinhlobo zamashubhu: | I-boiler tube, ishubhu enembile, ishubhu yemishini, ishubhu yesilinda, amapayipi omugqa, njll |

| I-Mill MTC: | Ihlinzekwa ngaphambi kokuthunyelwa |

| Ukuhlola: | Ukuhlolwa komuntu wesithathu kungamukelwa, i-SGS, i-BV, i-TUV |

| Mount port: | Noma yiliphi ichweba eChina |

| Isikhathi Sokuhweba: | FOB, CIF, CFR, EXW, njll. |

| Isikhathi senani: | TT noma LC lapho ubona |

| Amasevisi ethu: | Singakwazi ukwenza ngokwezifiso ngokuya ngesidingo sekhasimende noma umdwebo, ukupakishwa ngokwesicelo samakhasimende |

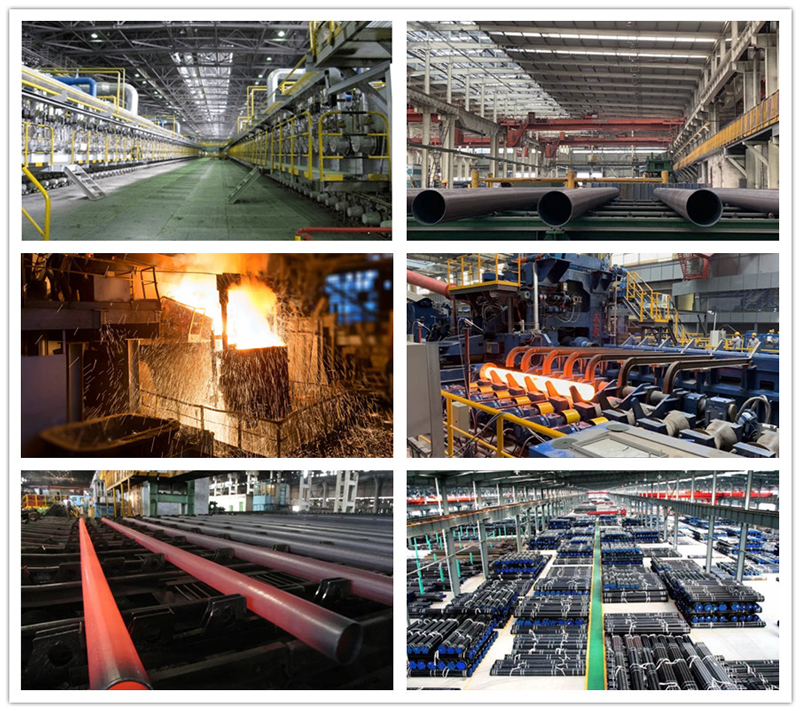

Umbukiso Wemboni