-

SA588 SA387 Ingxubevange Yensimbi Plate

Isethulo somkhiqizo:

Ngokusho kokuqukethwe kwezakhi ze-alloy kuhlukaniswe:

insimbi ephansi ye-alloy (inani eliphelele lezinto ze-alloy lingaphansi kuka-5%),

Insimbi ye-alloy ephakathi (5% -10% yezinto eziphelele ze-alloy)

Insimbi ephezulu ye-alloy (ingqikithi ye-alloy element ingaphezu kuka-10%).

Ngokuya nge-alloy element ukwakheka kube:

Insimbi ye-Chromium (Cr-Fe-C)

Insimbi ye-Chromium-nickel (Cr-Ni-Fe-C)

Insimbi yeManganese (Mn-Fe-C)

Insimbi ye-Silicon-manganese (Si-Mn-Fe-C)

-

Ipuleti Elingagugi, Ipuleti Elimelana Nesimo Sezulu

Isethulo somkhiqizo:

Ipuleti lensimbi elingagugi lakhiwe izingxenye ezimbili: ipuleti lensimbi elinekhabhoni ephansi kanye nongqimba olungagugi.Ungqimba olungagugi ingxubevange ngokuvamile luwu-1/3~1/2 wogqinsi oluphelele.Lapho usebenza, i-matrix ihlinzeka ngokusebenza okuphelele okufana namandla, ukuqina kanye nepulasitiki, futhi ungqimba oluqinile lwe-alloy lunikeza ukumelana nokugqoka ukuze kuhlangatshezwane nezidingo zezimo zokusebenza ezishiwo.

I-alloy wear-resistant layer i-chromium alloy, futhi i-manganese, i-molybdenum, i-niobium, i-nickel nezinye izakhi ze-alloy nazo zengezwa.I-carbide esicutshini se-metallographic isatshalaliswa ngendlela yefiber, futhi isiqondiso se-fiber sibheke phezulu.I-microhardness ye-carbide ingafinyelela ngaphezu kwe-HV1700-2000, futhi ubulukhuni bobuso bungafinyelela ku-HRC 58-62.I-alloy carbide inokuqina okuqinile ekushiseni okuphezulu, igcina ubulukhuni obukhulu, kodwa futhi inezindawo ezinhle zokulwa ne-antioxidant, ngaphakathi kwe-500 ℃ ukusetshenziswa okujwayelekile ngokuphelele.

-

I-SA516 Gr60 Gr70 SA387Gr22CL2 Isitsha Sesitsha

Isethulo somkhiqizo:

Isitsha sesitsha sisetshenziselwa ikakhulukazi ukusetshenziswa komkhumbi wengcindezi

-

I-S235JR S275JR S355JR I-Carbon Steel Plate

Isethulo somkhiqizo:

Amapuleti ensimbi ahlukaniswe abe amapuleti agoqwe ashisayo nabandayo.

Ngokwezinhlobo zensimbi, kunensimbi evamile, insimbi yekhwalithi ephezulu, insimbi ye-alloy, insimbi yasentwasahlobo, insimbi engagqwali, insimbi yamathuluzi, insimbi ekwazi ukumelana nokushisa, insimbi enensimbi, insimbi ye-silicon kanye neshidi lensimbi ehlanzekile yezimboni.

Ikhwalithi ephezulu ye-carbon structural steel ingahlukaniswa ngezigaba ezintathu ngokusho kokuqukethwe kwekhabhoni ehlukene: insimbi ye-carbon ephansi (C 0.25%), insimbi ye-carbon steel (C ingu-0.25-0.6%) kanye ne-carbon steel ephezulu (C & gt; 0.6%).

Ikhwalithi ephezulu ye-carbon structural steel ihlukaniswe ibe yi-manganese evamile (0.25% -0.8%) kanye ne-manganese ephakeme (0.70% -1.20%), yakamuva inezakhiwo ezinhle zemishini kanye nezakhiwo zokucubungula.

-

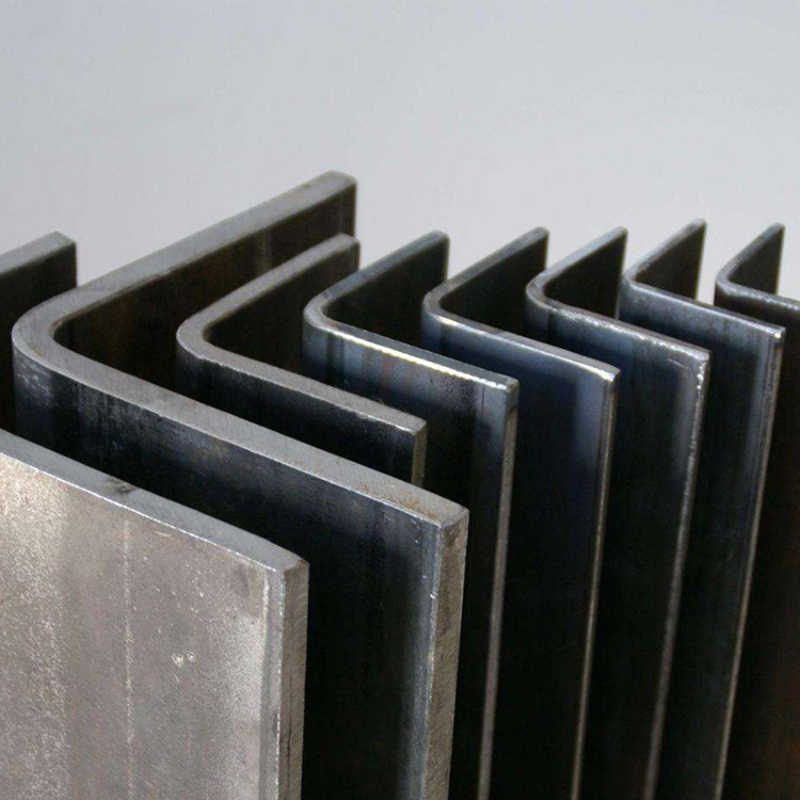

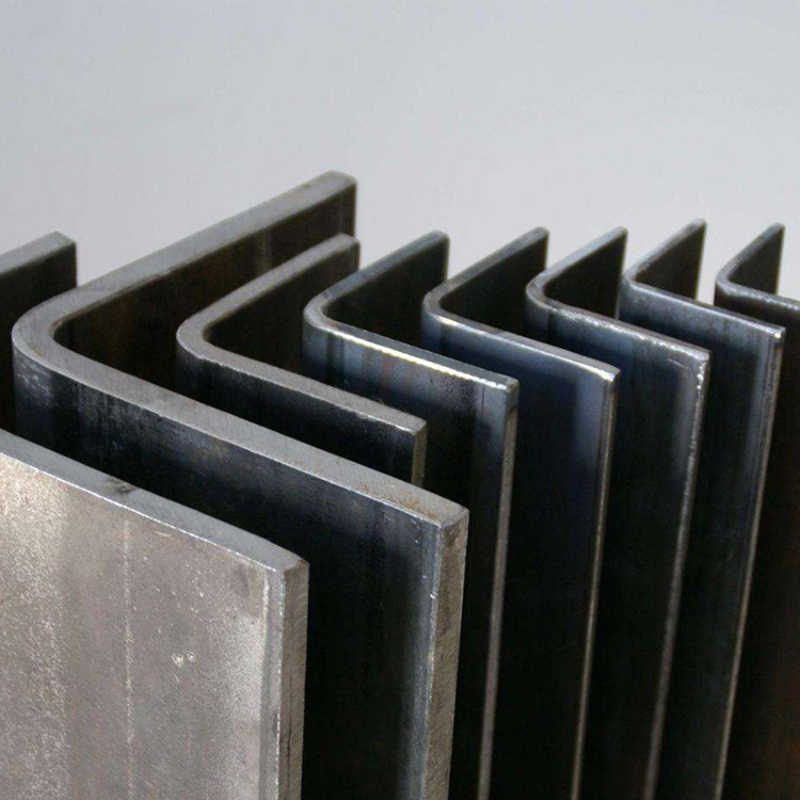

ST37 ST52 S235 JRS275 A36 A53 I-Angle Steel

Isethulo somkhiqizo:

I-Angle steel iyinsimbi emise okwe-L, ngokuvamile eyenziwa ngokugoqa okushisayo noma okubandayo.Ubude nosayizi wensimbi ye-engeli kungenziwa ngokwezifiso njengoba kudingeka.

Inqubo yokukhiqiza ye-Angle steel ngokuvamile ihlanganisa ukugoqa okushisayo nokucubungula okubandayo.Insimbi ye-Angle egoqiwe eshisayo ukushisa i-billet ekushiseni okuthile ngomgwaqo we-roller ngemva kokucindezela ukubunjwa, ukusebenza kahle kokukhiqiza kuphezulu, kodwa izindleko ziphakeme kakhulu.Ukucubungula ukugoba okubandayo kungomshini ukuze kwakhiwe ipuleti lensimbi le-pretreatment, izindleko ziphansi kodwa ukusebenza kahle kokukhiqiza kuphansi.

-

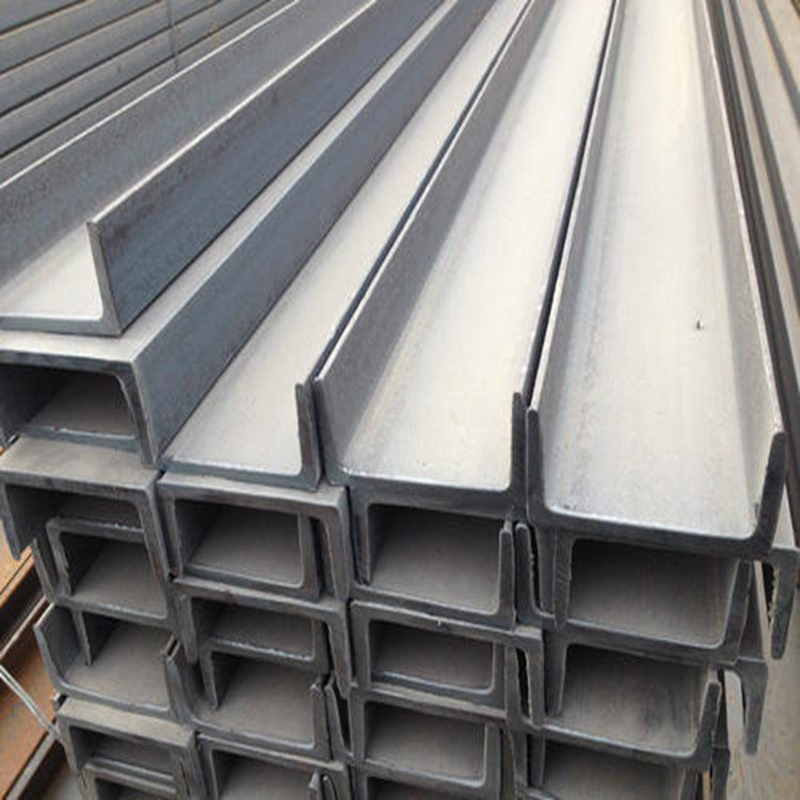

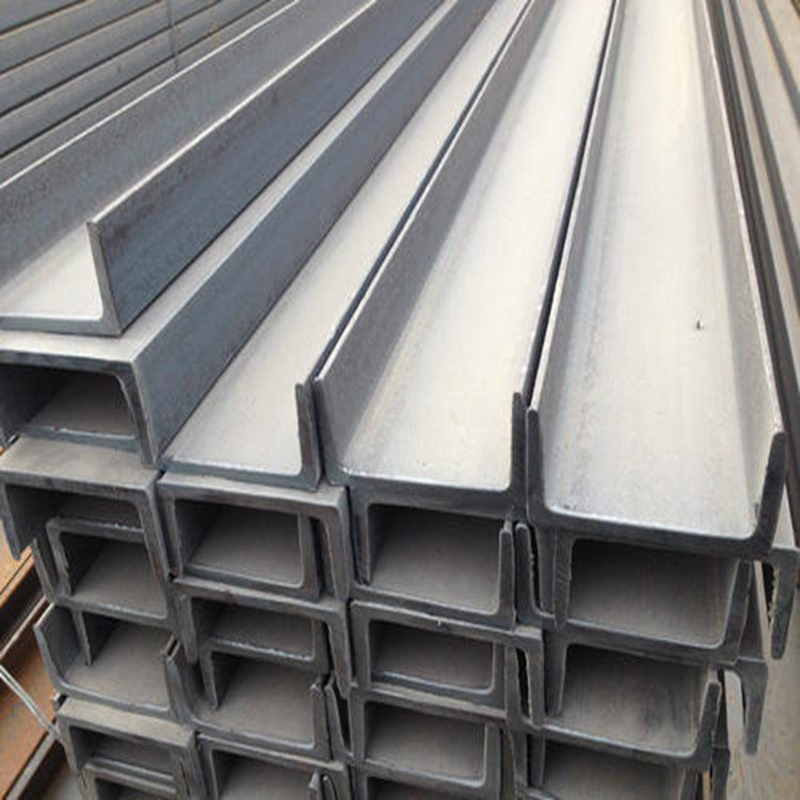

304, 310S, 316, 347, 2205 Stainless Channel Steel

Isethulo somkhiqizo:

Insimbi engagqwali ye-groove iyingxenye ende yensimbi emise okwe-groove, ingeyokwakhiwa kanye nensimbi yesakhiwo se-carbon mechanical, iyingxenye eyinkimbinkimbi yensimbi yesigaba, ukwakheka kwesigaba sayo kuyisimo se-groove.Ubude nosayizi wensimbi yesiteshi kungenziwa ngendlela oyifisayo njengoba kudingeka.

Inqubo yokukhiqiza yensimbi yensimbi engagqwali ngokuvamile ihlanganisa izindlela ezimbili: ukugoqa okushisayo kanye nokucubungula ukugoba okubandayo.I-hot rolling groove I-engeli yensimbi iwukushisa i-billet ezingeni lokushisa elithile ngeshaneli yerola ukuze ucindezele ukubunjwa.Ukugoba okubandayo kwenziwa ngomshini ukuze kwakheke ipuleti lensimbi lokwelashwa kwangaphambili.

Insimbi yensimbi engagqwali yenziwe ngensimbi yensimbi egoqiwe futhi ebandayo egoqiwe ngokugotshwa nokwenza.Inengxenye ye-groove futhi iyinto evamile emikhiqizweni eminingi yensimbi.Isetshenziswa kakhulu kwezokwakha, ekwenziweni kwemishini, kwe-petrochemical, izimboni kanye nezinkambu zokuhamba.

-

304, 310S, 316, 347, 2205 Stainless Round Bar Steel

Isethulo somkhiqizo:

I-Stainless Round steel iyinsimbi eqinile eyi-cylindrical, ububanzi bayo bungaklanywa ngamasayizi ahlukene ngokuya ngezidingo zokukhiqiza.Inqubo yokucubungula ihlanganisa ukugoqa okushisayo, ukudweba okubandayo, ukubumba nokwelashwa kokushisa nezinye izindlela.Phakathi kwazo, ukugoqa okushisayo kuyindlela evame ukusetshenziswa kakhulu, engakhiqiza insimbi eyindilinga enobubanzi obukhulu.Inqubo yokudweba ebandayo ingaveza ububanzi obuncane kanye nokunemba okuphezulu kwensimbi eyindilinga.

-

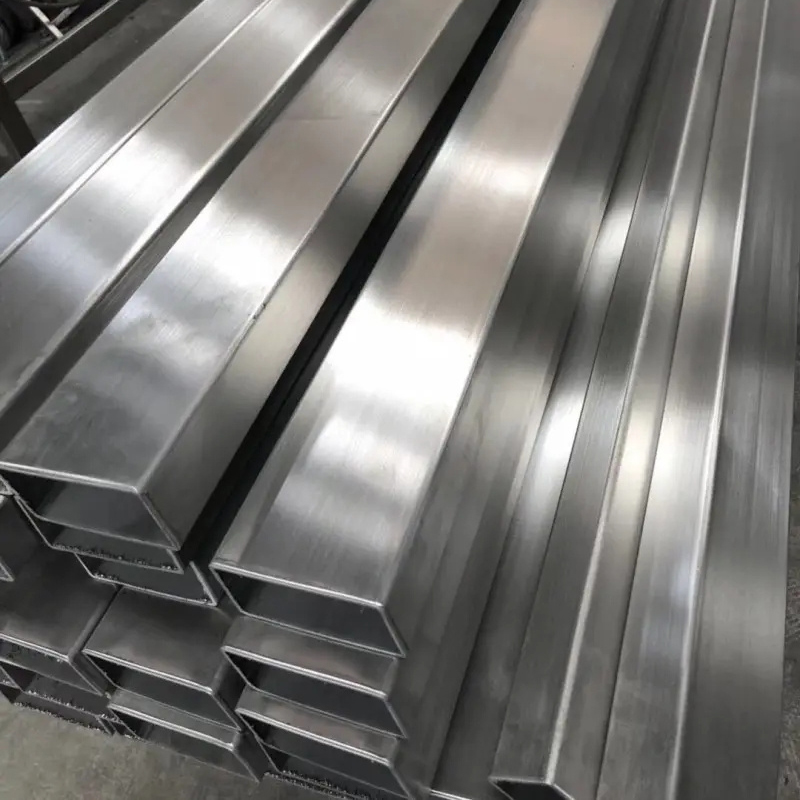

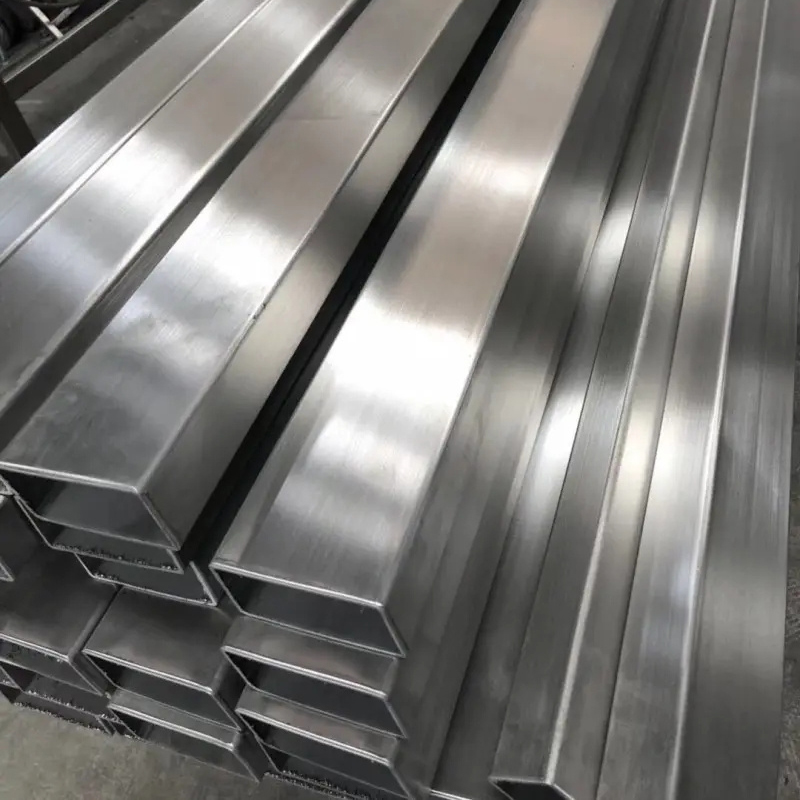

St52 A178 A53/304 316 347 Welded Square/Rectangular Tube

Isethulo somkhiqizo:

Ipayipi eliyisikwele liyipayipi lensimbi eliyisikwele elingenalutho elingenalutho, elaziwa nangokuthi iphrofayili egobayo yesiqandisi.Kungumugqa ogoqiwe oshisayo noma obandayo ogoqiwe noma ikhoyili njengesisekelo ngokugotshwa okubandayo bese kwenziwa nge-high frequency welding ye-square usayizi womumo wensimbi.Ngaphandle ukushuba odongeni futhi ukuqina, usayizi ekhoneni kanye bushelelezi ohlangothini zonke ukufinyelela noma ngisho lidlule izinga ukumelana ashiselwe abandayo ukwakha ipayipi square.Izakhiwo ezibanzi zemishini, ukushisela, izakhiwo zemishini ezibandayo nezishisayo kanye nokumelana nokugqwala kuhle, nokuqina okuhle kwezinga lokushisa eliphansi.

Ukusetshenziswa kwamapayipi okwakha, ukukhiqizwa kwemishini, amaphrojekthi okwakha insimbi, ukwakha umkhumbi, ukusekelwa kwamandla elanga, ubunjiniyela besakhiwo sensimbi, ubunjiniyela bamandla kagesi, indawo yokuphehla amandla, ezolimo nemishini yamakhemikhali, udonga lwamakhethini engilazi, i-chassis yemoto, isikhumulo sezindiza, ukwakhiwa kukabhayela, izinsimbi zomgwaqo onguthelawayeka, izindlu ukwakhiwa, imikhumbi yokucindezela, amathangi okugcina uwoyela, Amabhuloho, imishini yesiteshi samandla, ukuphakamisa imishini yokuthutha kanye nomunye umthwalo ophezulu wesakhiwo sokushisela, njll.

-

I-St37 St52 A214 A178 A53 A423 Ipayipi Elishiselwe Ngothayela, ERW

Isethulo somkhiqizo:

Ipayipi le-hot-dip galvanized ukwenza insimbi encibilikisiwe ne-iron matrix reaction futhi ikhiqize ungqimba lwe-alloy, ukuze i-matrix kanye nongqimba olunamathelayo kuhlanganiswe.I-hot galvanizing yipayipi lensimbi kuqala, ukuze kukhishwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokukhetha, ngokusebenzisa isixazululo se-ammonium chloride noma i-zinc chloride noma i-ammonium chloride ne-zinc chloride exutshwe ithangi lesisombululo, bese ithunyelwa endaweni eshisayo. cwilisa ithangi le-plating.I-hot-dip galvanizing inezinzuzo zokugqoka okufanayo, ukunamathela okuqinile nokuphila isikhathi eside.Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka ngesixazululo esincibilikisiwe sepayipi lensimbi elidiphu elishisayo, okwakha ungqimba olumelana nokugqwala noluqinile lwe-zinc-one iron alloy.I-alloy layer ihlanganiswe nongqimba oluhlanzekile lwe-zinc kanye ne-steel tube matrix, ngakho-ke ukumelana kwayo nokugqwala kunamandla.

-

I-API 5L 3PE Q345 St37 St52 Ipayipi Elishiselwe, ERW, Ipayipi Elishiselwe

Isethulo somkhiqizo:

I-billet esetshenziselwa ipayipi yensimbi yokushisela i-steel plate noma i-strip steel, ngenxa yenqubo yayo ehlukene yokushisela, ihlukaniswe ipayipi yokushisela esithandweni, ipayipi kagesi (i-resistance welding) kanye nepayipi ye-arc welding ezenzakalelayo.Ngenxa yezinhlobo zayo ezihlukene zokushisela, ihlukaniswe yaba amapayipi ashiselwe ngomthungo oqondile kanye namapayipi ashiselwe athandelene.Ngenxa yokuma kwayo kokuphela ihlukaniswe ipayipi eliyindilinga elihlanganisiwe kanye nohlobo oluhlukile (isikwele, isicaba, njll.) ipayipi elihlanganisiwe.

-

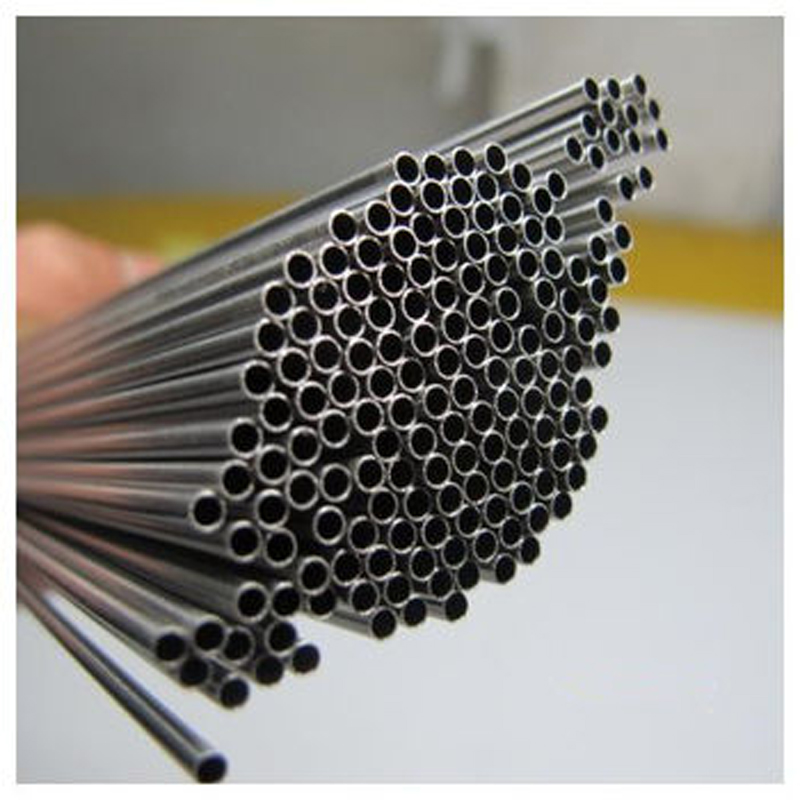

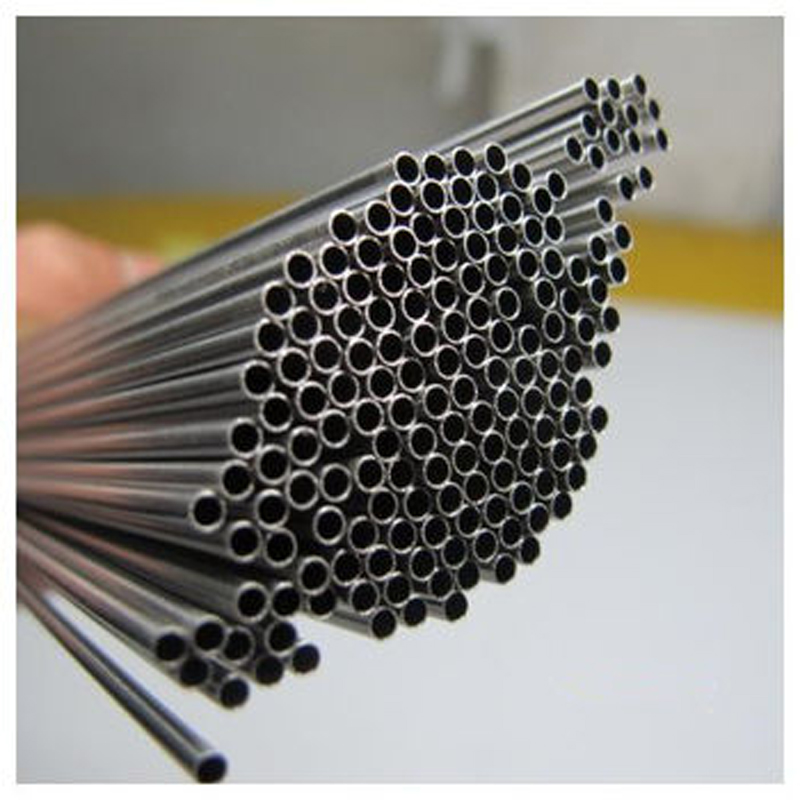

316L 347H S32205 Ipayipi Lensimbi Engenamthungo

Isethulo somkhiqizo:

Ukuhlukaniswa kwepayipi lensimbi engagqwali: ipayipi lensimbi engenamthungo kanye nepayipi lensimbi engagqwali elishiselwe (elinemithungo) izigaba ezimbili eziyisisekelo.Ngokusho kobubanzi obungaphandle bepayipi lensimbi lingahlukaniswa libe yipayipi eliyindilinga kanye nepayipi elimise okukhethekile, elisetshenziswa kabanzi yipayipi lensimbi eliyindilinga, kodwa kukhona nezinye isikwele, unxande, i-semicircular, hexagonal, unxantathu olinganayo, octagonal nezinye ezikhethekile. -ipayipi lensimbi elimise.

Ipayipi lensimbi engenamthungo lenziwe ngensimbi yensimbi noma i-billet yepayipi eliqinile ngokubhobozwa, bese kuba ngokudayela okugoqiwe okushisayo, okugoqiwe okubandayo noma okubandayo okwenziwe. -

201, 304, 347H, S32205 Stainless Steel Welded Pipe/ ERW

Isethulo somkhiqizo:

Ukuhlukaniswa kwepayipi lensimbi engagqwali: ipayipi lensimbi engenamthungo kanye nepayipi lensimbi engagqwali elishiselwe (elinemithungo) izigaba ezimbili eziyisisekelo.Ngokusho kobubanzi obungaphandle bepayipi lensimbi lingahlukaniswa libe yipayipi eliyindilinga kanye nepayipi elimise okukhethekile, elisetshenziswa kabanzi yipayipi lensimbi eliyindilinga, kodwa kukhona nezinye isikwele, unxande, i-semicircular, hexagonal, unxantathu olinganayo, octagonal nezinye ezikhethekile. -ipayipi lensimbi elimise.

Ngokusho kokusetshenziswa, ihlukaniswe ngamapayipi ashiselwe jikelele, ipayipi lokushisa lokushisa, ipayipi le-condenser, ipayipi elishiselwe, ipayipi le-oxygen, i-wire casing, ipayipi le-metric welded, ipayipi le-idler, ipayipi lepompo elijulile, ipayipi lemoto, ipayipi le-transformer, ugesi. welding mncane odongeni ipayipi, kagesi Welding ipayipi kanye Kuvunguza ashiselwe ipayipi.